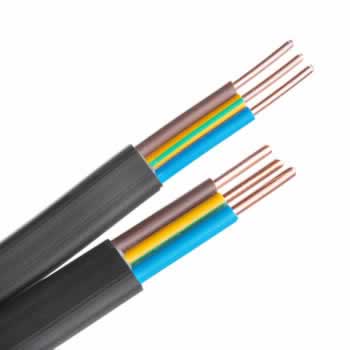

Wires and Cables

Wire and cable assemblies are essential components used in various industries to create efficient and reliable electrical connections. These assemblies consist of multiple wires or cables bundled together, often with connectors or terminals at each end. They play a crucial role in transmitting power, signals, and data between different components and systems. Wire and cable assemblies are designed to withstand various environmental conditions and mechanical stresses, making them suitable for a wide range of applications. From automotive and aerospace to electronics and industrial machinery, wire and cable assemblies are indispensable for ensuring the seamless flow of electrical energy and information. In this comprehensive product description, we will explore the world of wire and cable assemblies, their types, materials, applications, installation methods, and the valuable contributions they bring to modern electrical systems.

What are Wire and Cable Assemblies?

Wire and cable assemblies consist of multiple wires or cables that are bundled together, often with connectors or terminals at each end. These assemblies provide a means of efficiently transmitting electrical signals, power, or data between different components or systems. The wires and cables within the assembly are carefully selected and arranged to meet specific electrical requirements, ensuring optimal performance and reliability. Wire and cable assemblies can range from simple configurations with just a few wires to complex harnesses with hundreds of conductors, depending on the application's needs. These assemblies play a vital role in industries where precise and efficient electrical connections are essential for the functioning of equipment and devices.

Types of Wire and Cable Assemblies

Wire and cable assemblies come in a variety of types, each designed for specific applications and industries. Some common types include:

- Power Cables: Power cable assemblies are used for transmitting high electrical currents to provide power to various devices, machinery, and systems.

- Signal Cables: Signal cable assemblies are designed to transmit low-voltage signals or data between electronic components and systems.

- Coaxial Cables: Coaxial cable assemblies are used for high-frequency applications, such as telecommunications, data transmission, and video signals.

- Ribbon Cables: Ribbon cable assemblies consist of multiple conductors arranged side by side in a flat ribbon configuration, often used for space-saving applications.

- Fiber Optic Assemblies: Fiber optic cable assemblies use optical fibers to transmit data as pulses of light, providing high-speed data transmission and immunity to electromagnetic interference.

- Custom Harnesses: Custom wire and cable harnesses are tailored to specific applications, designed with precise wire lengths, connectors, and terminations to fit the exact requirements of the system.

- Electromechanical Assemblies: Electromechanical assemblies combine electrical and mechanical components, allowing the transmission of signals and power while enabling mechanical movements or actions.

- Multi-Conductor Cables: Multi-conductor cable assemblies consist of multiple insulated conductors within a single cable jacket, simplifying installation and reducing cable clutter.

- Medical Wire Assemblies: Wire and cable assemblies designed for medical devices and equipment, adhering to strict safety and regulatory standards.

- Automotive Wire Harnesses: Wire harness assemblies used in automotive applications, providing electrical connections for various vehicle components and systems.

Materials for Wire and Cable Assemblies

Wire and cable assemblies are manufactured using a variety of materials, each chosen based on factors such as electrical conductivity, insulation, temperature resistance, and application requirements. Common materials include:

- Copper: Copper is a widely used conductor material due to its excellent electrical conductivity and cost-effectiveness.

- Tinned Copper: Tinned copper conductors are coated with a thin layer of tin, providing better corrosion resistance and solderability.

- Aluminum: Aluminum conductors are lightweight and cost-effective, often used in certain industrial applications.

- Silver: Silver is a highly conductive material used in high-performance and high-frequency applications.

- Fiber Optics: Optical fibers are made of glass or plastic and are used for transmitting data as pulses of light.

- Insulation Materials: Common insulation materials include PVC, polyethylene, polypropylene, Teflon (PTFE), and silicone, each offering different levels of electrical insulation and temperature resistance.

- Outer Jacket Materials: Outer jackets are often made of PVC, polyurethane, neoprene, or thermoplastic elastomers (TPE), providing protection against abrasion, moisture, and environmental factors.

Wire and Cable Assemblies Applications

Wire and cable assemblies find applications in various industries and settings, including:

- Automotive: Automotive wire harness assemblies are used in vehicles for connecting electrical components, sensors, and systems, ensuring proper functionality and communication.

- Electronics: Wire and cable assemblies are essential in electronic devices and circuit boards, providing efficient connections for various components.

- Aerospace: These assemblies are used in aerospace applications for reliable electrical connections in aircraft and spacecraft systems.

- Telecommunications: Wire and cable assemblies play a vital role in telecommunications equipment and infrastructure, facilitating signal transmission and communication.

- Industrial Machinery: These assemblies are used in industrial machinery and equipment for electrical connections between motors, sensors, and control systems.

- Medical Devices: Wire and cable assemblies are utilized in medical devices and equipment, where reliable electrical connections are critical for patient safety and proper functionality.

- Power Distribution: These assemblies are used in power distribution systems to transmit electrical power from generation sources to end-users.

- Renewable Energy: Wire and cable assemblies are used in renewable energy systems, such as solar and wind power, for efficient power transmission and distribution.

- Consumer Electronics: These assemblies are found in various consumer electronic devices, such as computers, smartphones, and home appliances, ensuring efficient electrical connections for smooth operation.

- Marine: Wire and cable assemblies are used in marine applications, providing secure and corrosion-resistant electrical connections in boats, ships, and offshore equipment.

- Defense and Military: Wire and cable assemblies play a crucial role in defense and military applications, providing reliable electrical connections in military equipment, vehicles, and communication systems.

- Energy Transmission and Distribution: These assemblies are essential in energy transmission and distribution systems, ensuring efficient and reliable power delivery to homes and businesses.

- Railways: Wire and cable assemblies are used in railway systems for electrical connections in trains, signaling equipment, and railway infrastructure.

- Renewable Energy: These assemblies are employed in solar and wind power systems to create reliable connections for power generation and distribution.

- Construction: Wire and cable assemblies are used in construction projects for electrical connections in buildings and infrastructure.

- Oil and Gas: These assemblies find use in the oil and gas industry for electrical connections in drilling equipment and offshore platforms.

Installation Methods

The installation of wire and cable assemblies varies depending on the application and complexity of the assembly. Common installation methods include:

- Crimping: Crimping is a popular method for attaching connectors or terminals to the ends of wires or cables. Crimping tools are used to compress the connector onto the conductor, creating a secure and gas-tight connection.

- Soldering: Soldering is used to attach connectors or terminals to wires, providing a strong and reliable electrical connection.

- Connectorization: Many wire and cable assemblies come pre-fitted with connectors or terminals, simplifying the installation process by plugging them into corresponding receptacles.

- Splicing: Splicing is used to join two or more wires together, creating a continuous electrical pathway.

- Bundling and Clamping: Wires and cables are bundled together and secured using clamps or cable ties to organize and protect the assembly.

- Routing and Dressing: Proper routing and dressing of the assembly ensure that wires and cables are placed and secured neatly, minimizing the risk of damage and interference.

- Testing: After installation, wire and cable assemblies undergo testing to verify the integrity and functionality of the electrical connections.

Advantages of Wire and Cable Assemblies

Wire and cable assemblies offer numerous advantages that make them essential components in electrical systems and applications:

- Efficient Electrical Transmission: These assemblies provide efficient transmission of electrical power, signals, and data between components and systems.

- Reliability: High-quality materials and precise manufacturing ensure the reliability and longevity of wire and cable assemblies.

- Customizability: Wire and cable assemblies can be customized to fit the specific requirements of each application, ensuring optimal performance.

- Space-Saving: Ribbon cables and custom harnesses allow for space-saving configurations, especially in applications with limited space.

- Reduced Installation Time: Pre-fitted connectors or terminals streamline the installation process, reducing labor and assembly time.

- Flexibility: Wire and cable assemblies can be designed to be flexible or rigid, accommodating various installation environments and requirements.

- Signal Integrity: Shielded cable assemblies provide excellent signal integrity, reducing the risk of signal interference or degradation.

- Protection: Outer jacket materials provide protection against abrasion, moisture, and environmental factors, enhancing the assembly's durability.

- Compliance: Wire and cable assemblies can be manufactured to comply with industry standards and regulations, ensuring safety and compatibility.

- Cost-Effectiveness: Customized wire and cable assemblies offer cost-effective solutions for establishing reliable electrical connections, reducing the need for extensive on-site assembly.

- Easy Maintenance: Properly designed wire and cable assemblies allow for easier maintenance and troubleshooting in case of issues.

Conclusion

In conclusion, wire and cable assemblies are vital components that enable efficient and reliable electrical connections in a wide range of industries and applications. From automotive and aerospace to electronics and power distribution, these assemblies play a critical role in ensuring the seamless flow of electrical energy and information. With a variety of types, materials, and installation methods available, wire and cable assemblies offer versatile solutions to meet the specific needs of different electrical systems.

As technology continues to advance, wire and cable assemblies will remain essential components in electrical design and assembly. Manufacturers, engineers, and industries can rely on these assemblies to create efficient, durable, and cost-effective electrical connections, contributing to the success and reliability of various products, equipment, and systems.