Spacers and Standoffs

Spacers and standoffs are essential components used in various industries to provide precise spacing and alignment between two or more objects. These versatile components play a crucial role in electronic, automotive, aerospace, and industrial applications, ensuring proper positioning and secure assembly of components. Spacers are cylindrical or tubular pieces with uniform outer diameters, while standoffs have a threaded design, allowing them to be securely fastened to a surface. Both spacers and standoffs come in various sizes, materials, and configurations to accommodate the unique requirements of different projects and applications. In this comprehensive product description, we will explore the world of spacers and standoffs, their types, materials, applications, installation methods, and the valuable contributions they bring to modern industrial assembly processes.

What are Spacers and Standoffs?

Spacers and standoffs are mechanical components used to create precise gaps or clearances between objects while ensuring proper alignment and stability. These components prevent direct contact between surfaces, reducing friction and potential damage caused by metal-to-metal contact. Spacers are typically non-threaded and are available in various lengths, while standoffs have a threaded design that allows them to be easily fastened to surfaces, providing secure support for assembled parts. Both spacers and standoffs are used in situations where precise positioning, alignment, and spacing are critical, such as in electronic circuits, automotive assemblies, and industrial machinery.

Types of Spacers and Standoffs

Spacers and standoffs come in a variety of types to suit different applications and assembly requirements. Some common types include:

- Round Spacers: Round spacers have a cylindrical shape with a uniform outer diameter, providing even spacing between components.

- Hex Spacers: Hex spacers have a hexagonal shape, allowing for easy installation and removal with a wrench.

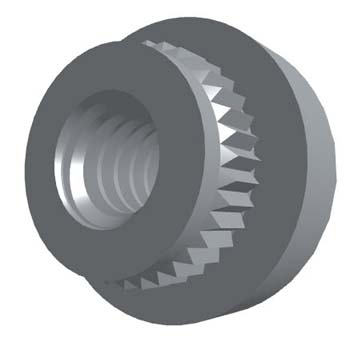

- Standoffs with Internal Threads: These standoffs have internal threads that enable them to be securely fastened to a surface, creating a raised connection point.

- Standoffs with External Threads: These standoffs have external threads and are often used to create space between two surfaces while providing a threaded connection.

- Swage Standoffs: Swage standoffs, also known as self-clinching standoffs, are designed to be permanently installed in thin metal sheets using a swaging process.

- Male-Female Standoffs: These standoffs have different thread types on each end, enabling them to create a connection between two components with different thread sizes.

- Clearance Spacers: Clearance spacers have a larger outer diameter, providing additional clearance for bolts or screws passing through them.

- Shoulder Washers: Shoulder washers have a smaller inner diameter and are used to create a smooth surface transition between a screw head and the assembly.

Materials for Spacers and Standoffs

Spacers and standoffs are manufactured from a wide range of materials to meet various application requirements. Common materials include:

- Steel: Steel spacers and standoffs are strong and durable, making them suitable for industrial and heavy-duty applications.

- Stainless Steel: Stainless steel spacers and standoffs offer excellent corrosion resistance, making them ideal for outdoor and marine use.

- Aluminum: Aluminum spacers and standoffs are lightweight and corrosion-resistant, often used in aerospace and electronics.

- Brass: Brass spacers and standoffs provide an aesthetically pleasing finish and are commonly used in decorative applications.

- Nylon: Nylon spacers and standoffs are lightweight, non-conductive, and resistant to chemicals, making them suitable for electrical and electronic applications.

- Plastic: Plastic spacers and standoffs come in various materials, including ABS, PVC, and polycarbonate, offering versatility and lightweight properties.

- Phenolic: Phenolic spacers and standoffs are known for their electrical insulation properties and are used in electronic circuits.

- Ceramic: Ceramic spacers and standoffs are non-conductive, heat-resistant, and provide excellent electrical insulation, commonly used in high-temperature applications.

Spacers and Standoffs Applications

Spacers and standoffs find applications in various industries and settings, including:

- Electronics: Spacers and standoffs are widely used in electronic circuits to provide precise spacing between PCBs, components, and enclosure panels.

- Automotive: These components are used in automotive assemblies to maintain proper spacing and alignment of various parts and components.

- Aerospace: Spacers and standoffs are essential in aerospace applications for securing and aligning critical components in aircraft structures.

- Industrial Machinery: These components are used in industrial machinery and equipment to ensure precise alignment and spacing of mechanical parts.

- Telecommunications: Spacers and standoffs find use in telecommunications equipment for spacing and alignment of internal components.

- Medical Equipment: Spacers and standoffs are used in medical devices and equipment to maintain precise spacing and alignment of components, ensuring the proper functioning of critical instruments and machinery.

- Renewable Energy: In the renewable energy sector, spacers and standoffs are employed in solar panels and wind turbines to maintain proper spacing and alignment for optimal energy efficiency.

- Construction: These components are used in construction projects for spacing and aligning architectural elements, providing stability and precision in building structures.

- Consumer Electronics: Spacers and standoffs are commonly used in consumer electronic devices, such as computers and smartphones, to provide accurate spacing and alignment between internal components.

- Furniture: In the furniture industry, spacers and standoffs are utilized for assembly, providing precise spacing and alignment of furniture components for both functional and aesthetic purposes.

- Robotics: Spacers and standoffs play a critical role in robotics and automation, ensuring precise positioning and alignment of robotic arms and components.

Installation Methods

The installation of spacers and standoffs depends on their type and design. Some common installation methods include:

- Push-Fit: Non-threaded spacers are often installed using a push-fit method, simply pressing them into the desired location to create the required spacing.

- Threaded Installation: Standoffs with external threads are installed by screwing them into pre-drilled or tapped holes on the mounting surface.

- Swaging: Swage standoffs are permanently installed in thin metal sheets by using a swaging tool to compress the material around the standoff's shank.

- Adhesive Bonding: Some spacers and standoffs can be installed using adhesive bonding, providing a secure and clean installation without the need for drilling or tapping.

Advantages of Spacers and Standoffs

Spacers and standoffs offer numerous advantages that make them essential components in modern industrial assembly processes:

- Precision: These components provide precise spacing and alignment, ensuring accurate positioning of components and parts.

- Versatility: With a wide range of types, materials, and configurations available, spacers and standoffs are versatile components suitable for diverse applications.

- Strength and Stability: Spacers and standoffs are designed to withstand various forces and vibrations, providing stable and durable assembly solutions.

- Electrical Insulation: Certain materials, such as nylon, phenolic, and ceramic, offer excellent electrical insulation properties, making them suitable for electronic applications.

- Corrosion Resistance: Stainless steel, aluminum, and plastic spacers and standoffs offer excellent corrosion resistance, ensuring long-lasting performance in harsh environments.

- Reduction of Wear and Friction: By creating a barrier between two surfaces, spacers and standoffs reduce wear and friction, prolonging the life of assembled components.

- Easy Installation: Spacers and standoffs can be easily installed using various methods, simplifying assembly processes and reducing production time.

- Aesthetic Appeal: Brass and aluminum spacers and standoffs add an aesthetically pleasing finish to assemblies, enhancing the overall appearance of the final product.

- Temperature and Chemical Resistance: Certain materials, like ceramic and phenolic, offer excellent resistance to high temperatures and chemicals, making them suitable for extreme environments.

- Cost-Effective: Spacers and standoffs provide cost-effective solutions for achieving precise spacing and alignment, reducing the need for custom-made parts or complex assembly methods.

Conclusion

In conclusion, spacers and standoffs are indispensable components that offer precise spacing, alignment, and stability in a wide range of industrial applications. From electronics and automotive to aerospace and robotics, these versatile components play a critical role in ensuring the proper assembly and functioning of various products and equipment. With a vast array of types, materials, and installation methods available, spacers and standoffs provide tailored solutions to meet the unique requirements of different industries and projects.

As industries continue to pursue advancements in technology, efficiency, and reliability, spacers and standoffs will remain essential components, contributing to the success and innovation of modern industrial assembly processes. Manufacturers and designers alike can rely on these versatile components to achieve precision, durability, and cost-effectiveness in their assemblies, enhancing the overall performance and quality of their products.