Broaching Type Standoffs

Welcome to our comprehensive product description for Broaching Type Standoffs. In this guide, we will delve into the world of these innovative and precision-engineered components that provide secure and professional mounting solutions. Broaching type standoffs are designed to elevate your displays, signage, artwork, and electronic assemblies, offering exceptional strength and reliability for various industrial and commercial applications.

What are Broaching Type Standoffs?

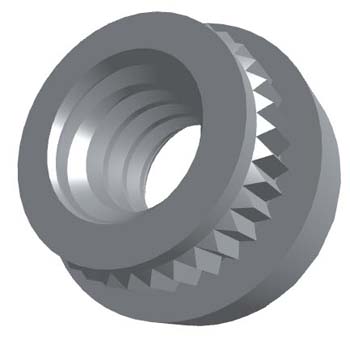

Broaching type standoffs are specialized fasteners that provide spacing and elevation between two components, typically panels or circuit boards. They are engineered with a unique broaching feature that allows for quick and secure installation into materials like metal, plastic, and composites. Broaching standoffs are the preferred choice for applications where traditional mounting methods may not be suitable or aesthetically pleasing. The precision broaching process creates clean and precise threads, ensuring a tight and stable fit.

Key Features and Benefits

Broaching type standoffs offer a plethora of features and benefits that make them a popular choice among engineers and designers. Let's explore some of their key advantages:

- Precision Engineering: Broaching standoffs are manufactured with high precision, ensuring consistent and accurate dimensions for a perfect fit.

- Secure Mounting: The broaching feature creates strong and reliable threads, providing a secure hold between components.

- Various Lengths and Diameters: Available in a wide range of lengths and diameters to accommodate diverse spacing requirements.

- Versatility: Suitable for mounting signs, displays, artwork, electronic assemblies, and more in various industries.

- Enhanced Aesthetics: The sleek design of broaching standoffs offers a clean and professional appearance to your installations.

- Time-Saving: The broaching installation process is quick and efficient, saving valuable time during assembly.

- Durable Materials: Manufactured from high-quality materials, such as stainless steel and aluminum, for excellent durability and corrosion resistance.

- Insulation and Isolation: Broaching standoffs can provide electrical insulation and component isolation in certain applications.

- Indoor and Outdoor Use: Designed to withstand various environmental conditions, making them suitable for both indoor and outdoor installations.

Applications

Broaching type standoffs find diverse applications across a wide range of industries. Some common areas where these standoffs excel include:

- Signage and Displays: Perfect for mounting office signage, directory displays, and retail product displays.

- Art Galleries and Museums: Used for mounting artwork, exhibit information, and display panels.

- Electronics and Circuit Boards: Ideal for creating separation and insulation between circuit board components.

- Architectural Applications: Utilized in architectural installations to create spacing between panels and cladding.

- Interior Design: Enhance interior design by using broaching standoffs to mount decorative panels and fixtures.

- Audio-Visual Equipment: Suitable for mounting screens, AV equipment, and speaker enclosures.

- Automotive: Used for mounting interior panels, dashboard displays, and electronic components.

- Industrial Machinery: Securely mount control panels and electronic displays on industrial machinery.

Installation Process

The installation of broaching type standoffs is a straightforward process that involves the following steps:

- Prepare the Workpiece: Ensure that the material is clean, and the spacing requirements are identified.

- Drill or Punch Hole: Create a pilot hole in the desired location using a drill or punch tool.

- Insert Broaching Standoff: Insert the broaching standoff into the pilot hole and apply gentle pressure.

- Turn Clockwise: While applying downward pressure, turn the standoff clockwise until it is firmly seated.

- Test and Secure: Verify the standoff's stability and make adjustments if necessary to ensure a secure mount.

Quality Assurance and Certifications

Our broaching type standoffs are meticulously manufactured to meet stringent quality standards and industry certifications. We are committed to providing products that consistently meet or exceed customer expectations. Our production facilities adhere to ISO 9001 and other relevant quality management systems, ensuring the highest level of quality and reliability in every standoff we produce.

Conclusion

Optimize the ease of installation and reliability of your projects with our Broaching Type Standoffs. Whether you require standoffs for PCB mounting, electronic enclosures, or industrial assemblies, our selection offers reliable solutions that ensure a seamless fit and secure fastening. Experience the efficiency and precision of our broaching type standoffs by exploring our diverse range today.